Stories – 75 years in business

75 years in business – How Comet is exploring for better

Enlightening, or: The world’s most powerful x-ray tube.

By developing the 600 kV x-ray tube, Comet blazed a trail where no one had gone before. The path to success was long and rocky.

“Comet achieves breakthrough in x-ray technology,” proclaims the headline of the Swiss business newspaper “Finanz und Wirtschaft” on October 15, 2011. The groundbreaking innovation reconciles extremes of large and small: Even relatively huge objects can be x-rayed in minute detail thanks to this Comet technology. In the words of the newspaper: “Structures barely thicker than a human hair can be recognized in components that are several square meters in size.” Making this possible is the 600 kilovolt x-ray source that enables three-dimensional imaging in stunning resolution.

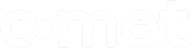

This technological breakthrough almost eluded Comet. Let’s take a look back at its origin. In 2006, the company’s X-Ray Tubes department, now the Industrial X-Ray Modules division (IXM), has to acknowledge that its most powerful tubes, those with an operating voltage of 450 kilovolts (kV), no longer meet the needs of numerous customers. They now require stronger tubes that allow even larger products and denser materials to be inspected in little time – for example, to screen steel shipping containers at customs, or for non-destructive inspection of high-absorbing turbine blades in aircraft engines. The mission for the R&D department is clear: A new x-ray tube with 600 kilovolts of power is needed!

The task is formidable: How can 600 kV – that is 600,000 volts, or 40 times the voltage of a suburban railroad overhead line – be reliably insulated in a 35-centimeter-long metal-ceramic tube for several thousand hours of operation? So far, no one has managed to do this. The developers at the X-Ray Tubes department get to work.

The hard work and perseverance pay off. In the fall of 2011, Comet can declare victory: The 600 kV x-ray tube is ready for the market – and immediately finds buyers worldwide. A Chinese customer uses it to test ceramic tiles for aerospace applications, and a little later a customer from the USA orders ten modules at once – tube, high-voltage generator, controller and cooler – for several hundred thousand Swiss francs.