Environmental

Materials Compliance

Materials compliance is compliance with any laws, regulations and specifications that restrict or even prohibit the use of various substances and/or materials in products, including, for instance, environment-related legislation, international law, religiously motivated specifications and specifications by companies. As a manufacturer of industrial products, an indispensable requirement for doing business worldwide is compliance with regulations relevant to the environment and market access – such as Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), Restriction of Hazardous Substances (RoHS), and the Toxic Substances Control Act (TSCA) – as well as with legislation driven by international law and ethics, including Conflict Minerals legislation, the Dodd-Frank Act and Regulation (EU) 2017/821.

We are committed to provide our customers with the highest-quality supply chain that meets all established product performance standards and expectations. Our purchasing department maintains these high standards by continuously evaluating the performance of our established suppliers.

Comet's Supplier Code of Conduct (Supplier CoC) is based on the Code of Conduct of the Responsible Business Alliance (RBA) and sets out the basic requirements for our suppliers and external service providers regarding their responsibility toward their stakeholders and the environment. We reserve the right to amend the requirements of our Supplier CoC to reflect changes in our compliance policies.

In addition to supplier self-declaration in the form of the signed Supplier CoC, we work with third-party supply chain specialist Assent Compliance Inc. The Assent platform collects the data required to comply with REACH, RoHS, Conflict Minerals and TSCA. This solution provides assurance that our suppliers are compliant with all relevant laws and regulations. Suppliers who do not submit data to Assent are contacted directly by us and requested to provide the necessary documentation. When appropriate, we work together with our suppliers to identify actions to achieve improvement. However, we reserve the right to terminate the business relationship with the supplier subject to applicable laws if the supplier fails to comply with the code, and we reserve the right to take legal action against the supplier.

The responsibilities for the processes are mapped in the Comet Group management system. Essentially, the specifications for materials compliance are made at the Group level by the Vice President of Global Operational Excellence (VP GOE), who reports directly to the CEO. The VP GOE defines the compliance regulations together with the Group legal experts. The responsibility for implementation in the regions rests with the divisions, and accountability for it lies with the respective country general managers. Materials compliance activities are coordinated worldwide within the Quality & Excellence Board.

Environmental Management System and Compliance

The principle of sustainability is an integral part of Comet’s corporate culture. We strive to offer our customers high-quality products and services while avoiding environmental risks and producing in a resource-conserving manner. The principles of this approach are set out in the Comet Group’s Quality, Environmental and Safety Policy, with supplementary information in the Code of Conduct.

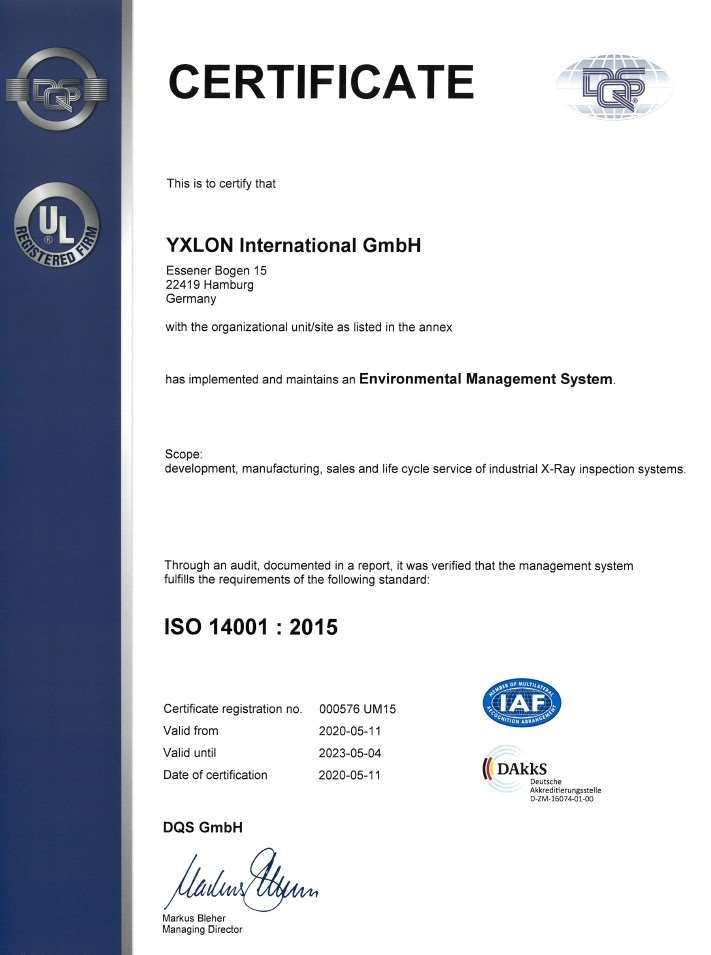

While all our production and research and development sites are certified to ISO 9001:2015, only Yxlon International (IXS division) in Hamburg has designed and implemented an environmental management system in accordance with ISO 14001:2015. Smaller entities with only sales and marketing activities are not certified. To ensure compliance with environmental regulations, however, internal audits, customer and certification audits, benchmarking and best-practice applications are conducted at regular intervals at all production sites.

Comet plans to achieve one single Group-wide ISO 9001 and ISO 14001 certification by 2023. As most of Comet’s major sites will be due for recertification in 2023, that year will be a natural opportunity to unify the quality management systems and achieve single certification.

The Vice President of Global Operational Excellence (VP GOE) is responsible for the performance of the Comet quality management system, including the process framework and architecture. The VP GOE drives the definition, implementation, and improvement of Group-wide processes in close cooperation with the divisions. Among other responsibilities, the VP GOE sets minimum standards for non-financial KPIs and ensures certification and compliance with ISO standards. In this function, support comes from various boards and councils, such as the Operations Council and the Quality & Excellence Board, which includes the Q&E heads of the divisions. Accountability for environmental compliance lies with the country general manager of each country, while responsibility for this topic lies with the division country manager. In the year under review, the Comet Group did not face any ongoing or completed proceedings for non-compliance with environmental laws or regulations. Likewise, no fines were imposed on the company.

We are fully committed to developing a roadmap for our Group-wide production to become more energy-efficient and increase the share of green electricity in our energy mix. In a broader context, we also started to further refine the Group’s approach to energy management and emission reduction.

For energy management and carbon emissions, the same management approach with the same roles and responsibilities is followed as described in the section on the material topic of “environmental management systems and compliance”.

In order to achieve sustainable ongoing improvements in our electricity consumption and thus our environmental performance, we launch several projects each year to increase our energy efficiency.