Trends harnessed as growth drivers

With its technologies, the COMET Group plays an important part in bringing greater safety and security, mobility, sustainability and efficiency to many areas of life. In growing through new applications, its focus is squarely on serving global trends. The Group sees particularly high growth potential in the Internet of Things and in the trends toward 3D tech- nologies, highly functional materials and resource-conserving, efficient processes.

3D – the third dimension

Whether in the 3D printing of components, the fabrication of 3D memory chips or the sterilization of three-dimensional surfaces, the third dimension has universal relevance in manufacturing. The technologies of the COMET Group help industry master its manufacturing challenges.

Radio frequency power

The semiconductor industry is making the shift to 3D chips. These are computer chips that are built up into the third dimension, analogous to high-rise buildings, in order to achieve more performance in the same or smaller space. However, the fabrication of these very powerful chips is demanding. It requires faster and more exact processes in the plasma chamber – processes that are controlled using our RF technology. The Group's PCT segment is always working to help its customers make their processes more rapid and precise.

X-ray

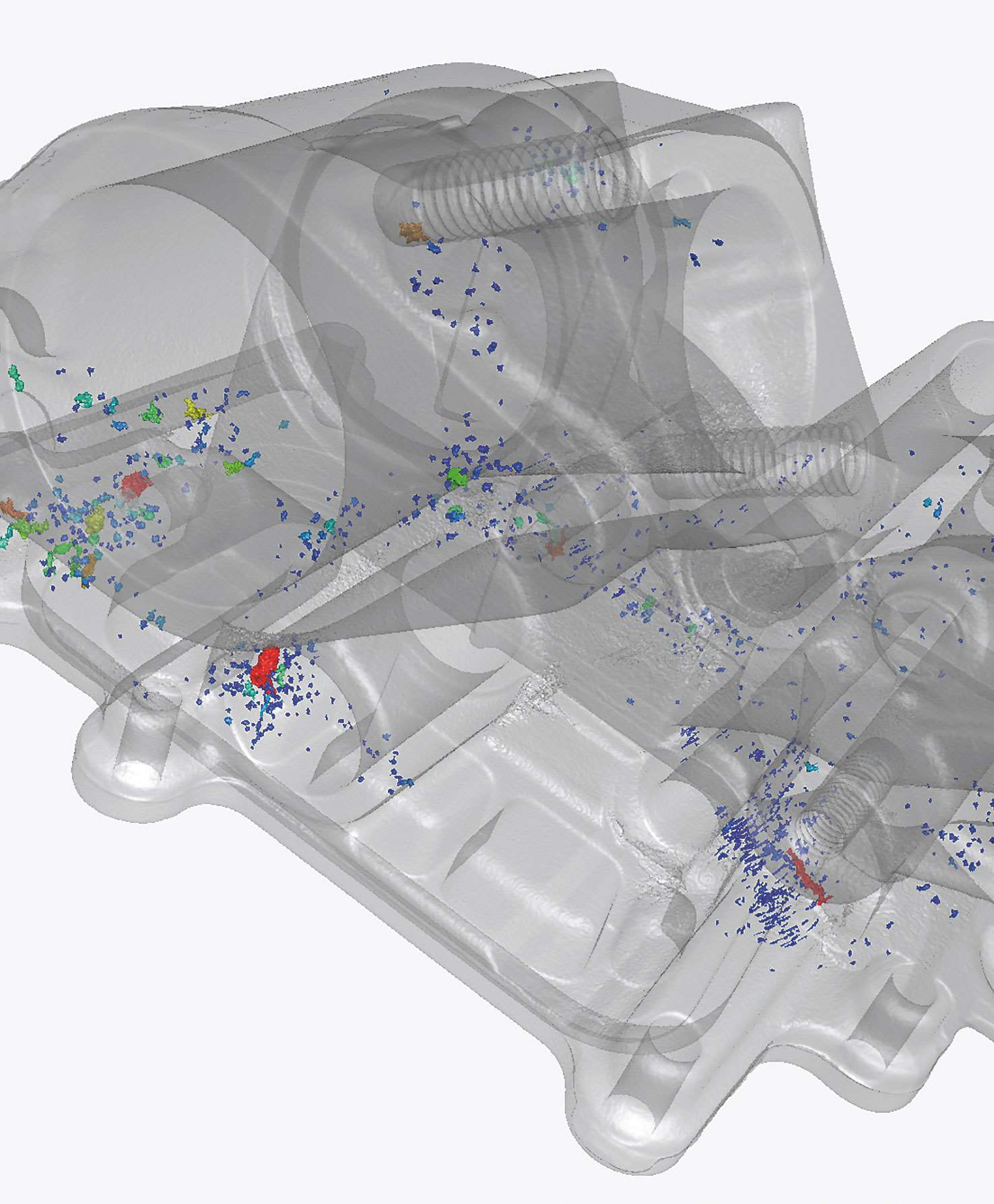

Additive manufacturing methods (also known as 3D printing) are becoming more and more important in the production of complex components. X-ray technology is indispensable for visualizing the interior structure of these components and for defect recognition. With it, customers can improve the quality of their processes, save resources and ensure the quality and safety of their products.

ebeam

ebeam technology is used to treat not only flat surfaces but also three-dimensional objects, such as cereals and spices. With ebeam, even three- dimensional surfaces can thus be effectively and non-chemically sterilized, inactivated or cured.